Finite Element Method Simulation

Physics Simulation, Continuum Mechanics, Large Deformations

- What I built: A comprehensive 3D Finite Element Method (FEM) solver for simulating volumetric object deformation.

- Why it matters: Accurately modeling physical materials is crucial for virtual reality, engineering, and visual effects.

- Proof: Robustly converges on large deformations using Neo-Hookean physics and Newton's Method.

Problem / Goal

Simulating the physical behavior of soft materials requires more than simple mass-spring systems. To capture realistic volume preservation and stress responses, we must model Continuum Mechanics.

The goal was to implement a robust 3D FEM solver capable of handling both small (Linear Elastic) and large (Neo-Hookean) deformations, solving for static equilibrium where internal elastic forces balance external loads.

My Contribution

I built the simulation engine from the ground up:

- Continuum Mechanics: Modeled deformation using the Deformation Gradient (F) and the First Piola-Kirchhoff stress tensor (P).

- Material Models: Implemented both Linear Elasticity (Hooke's Law) and Neo-Hookean hyperelasticity.

- Sparse Solvers: Assembled global Stiffness Matrices (K) and utilized sparse conjugate gradient solvers for efficiency.

- Nonlinear Optimization: Implemented Newton's Method with a backtracking line search to robustly solve the nonlinear energy minimization problem.

Technical Approach

1. Stiffness Matrix Assembly

A critical part of FEM is assembling the global stiffness matrix from element-wise contributions. This function computes the derivative of force with respect to position, effectively the "spring constant" for the entire mesh.

def stiffness_matrix(self, vertices: array) -> spmatrix:

""" Computes the global sparse stiffness matrix K. """

# Iterate over all tet elements

for t in range(num_tets):

# ... (retrieve deformation gradient F) ...

# Compute element contribution Kt = volume * dP/dx * dF/dx

# Chain rule: dP/dx = dP/dF * dF/dx

vol = volumes[t]

dP_dF = material.stress_differential(F)

dF_dxt = dF_dx[t]

dP_dxt = dP_dF @ dF_dxt

Kt = vol * dF_dxt.T @ dP_dxt

# Map local 12x12 matrix to global indices

for i in range(m):

for j in range(m):

triplets.append([index_map[i], index_map[j], Kt[i, j]])

# Construct the sparse matrix from triplets

K = csc_matrix((vals, (row_inds, col_inds)), shape=(N*dim, N*dim))

return K2. Neo-Hookean Material Model

The Neo-Hookean model extends linear elasticity to handle large rotations and deformations physically correctly. It uses the logarithm of the determinant of the deformation gradient ($J$) to enforce volume preservation (resisting compression to zero volume).

class NeoHookean(Material):

def energy_density(self, F: array) -> float:

"""

Compute energy density W for hyperelastic material.

W = 0.5 * mu * (I1 - dim - 2*log(J)) + 0.5 * lm * log(J)^2

"""

dim = F.shape[0]

I1 = np.dot(F.ravel(), F.ravel())

logJ = np.log(np.linalg.det(F))

W = 0.5 * self.mu * (I1 - dim - 2 * logJ) + 0.5 * self.lm * logJ ** 2

return W

def stress_tensor(self, F: array) -> array:

""" First Piola-Kirchhoff stress tensor P. """

F_invT = np.linalg.inv(F).T

logJ = np.log(np.linalg.det(F))

P = self.mu * (F - F_invT) + self.lm * logJ * F_invT

return PValidation / Results

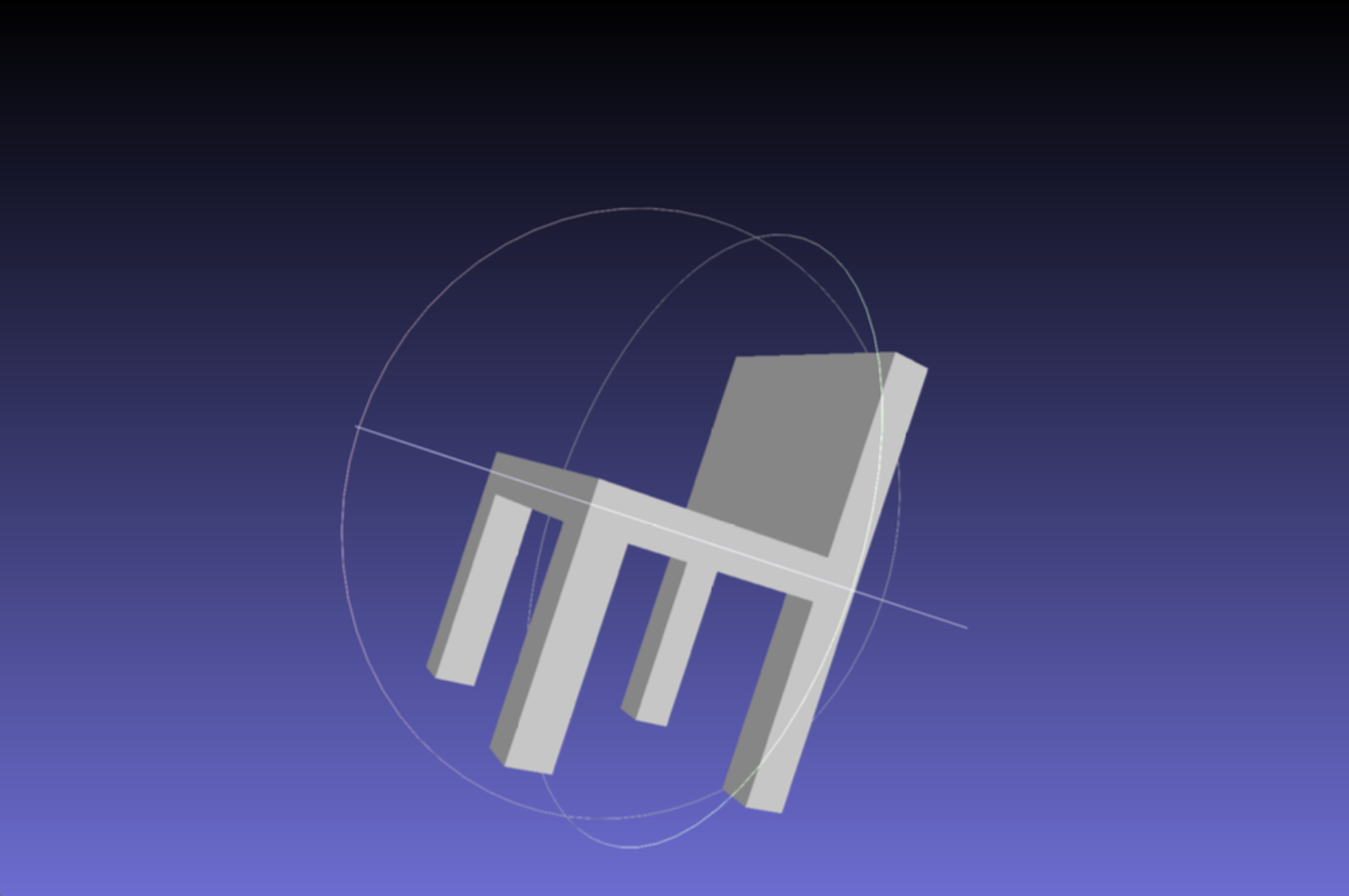

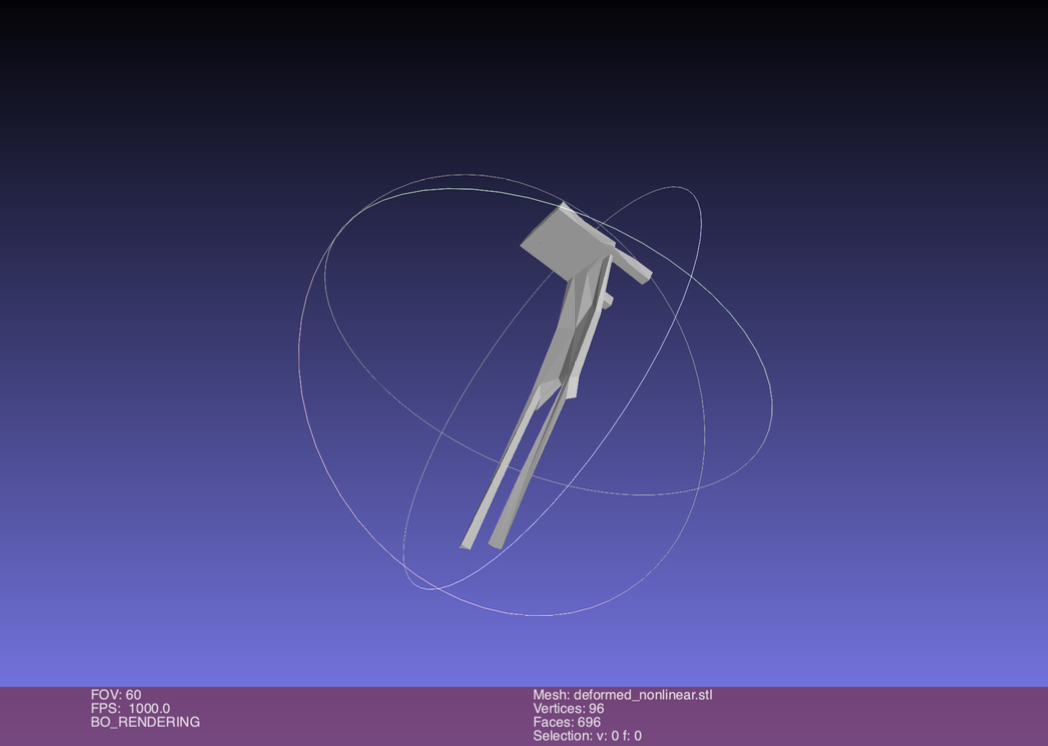

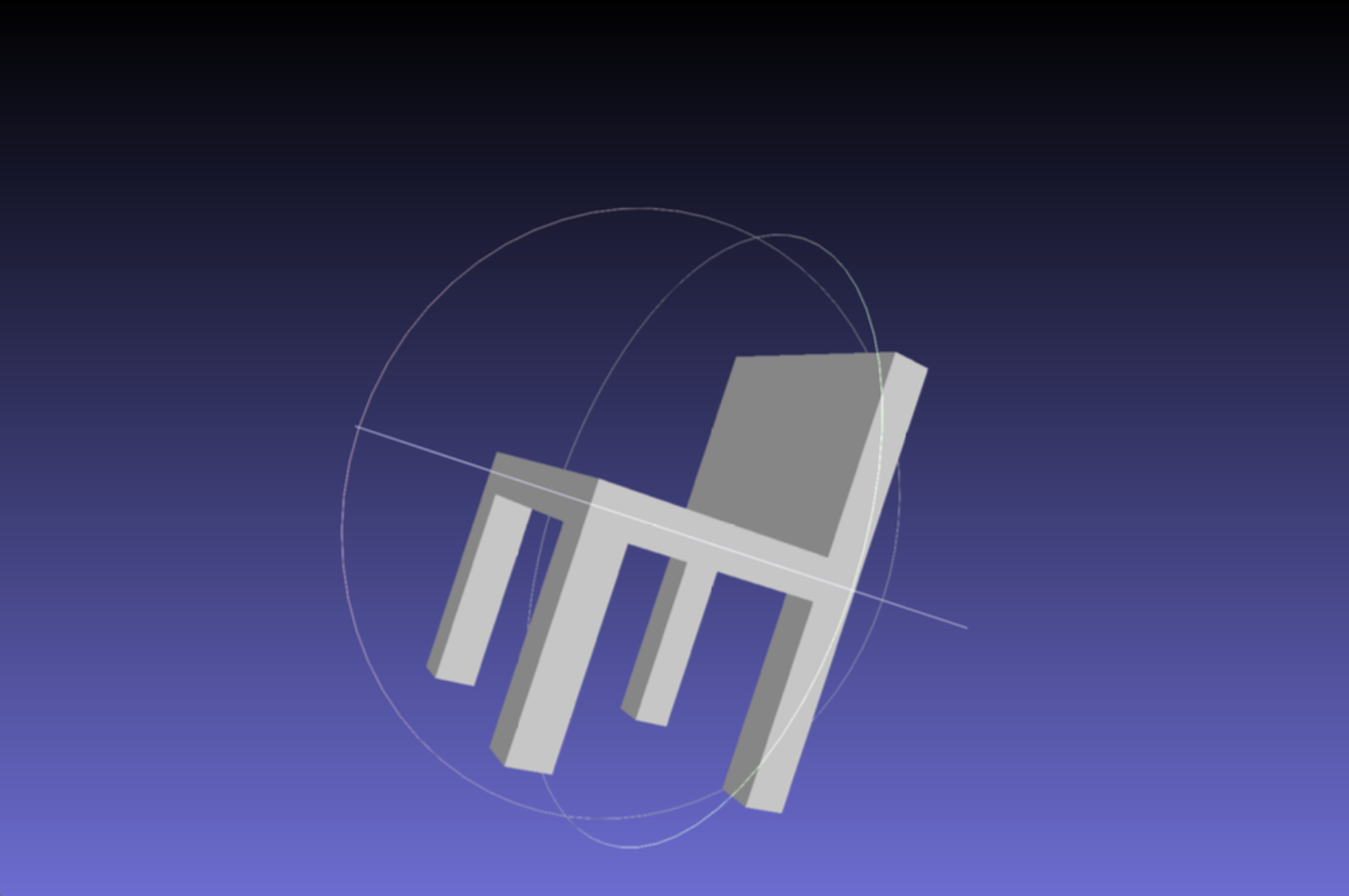

The simulation was validated by subjecting meshes to large gravity loads. The Neo-Hookean model correctly demonstrated nonlinear stiffening at high strains, unlike linear elastic models which would invert or "blow up."

Lessons + Next Steps

Lesson: Implementing standard Newton's Method is rarely enough for physics simulation. A robust line search (globalization strategy) is absolutely necessary to prevent the solver from taking steps that invert elements.

Next Steps: Extending the system to support dynamic simulation with implicit time integration (Backward Euler) for stable motion.