Knitted Soft Sensors

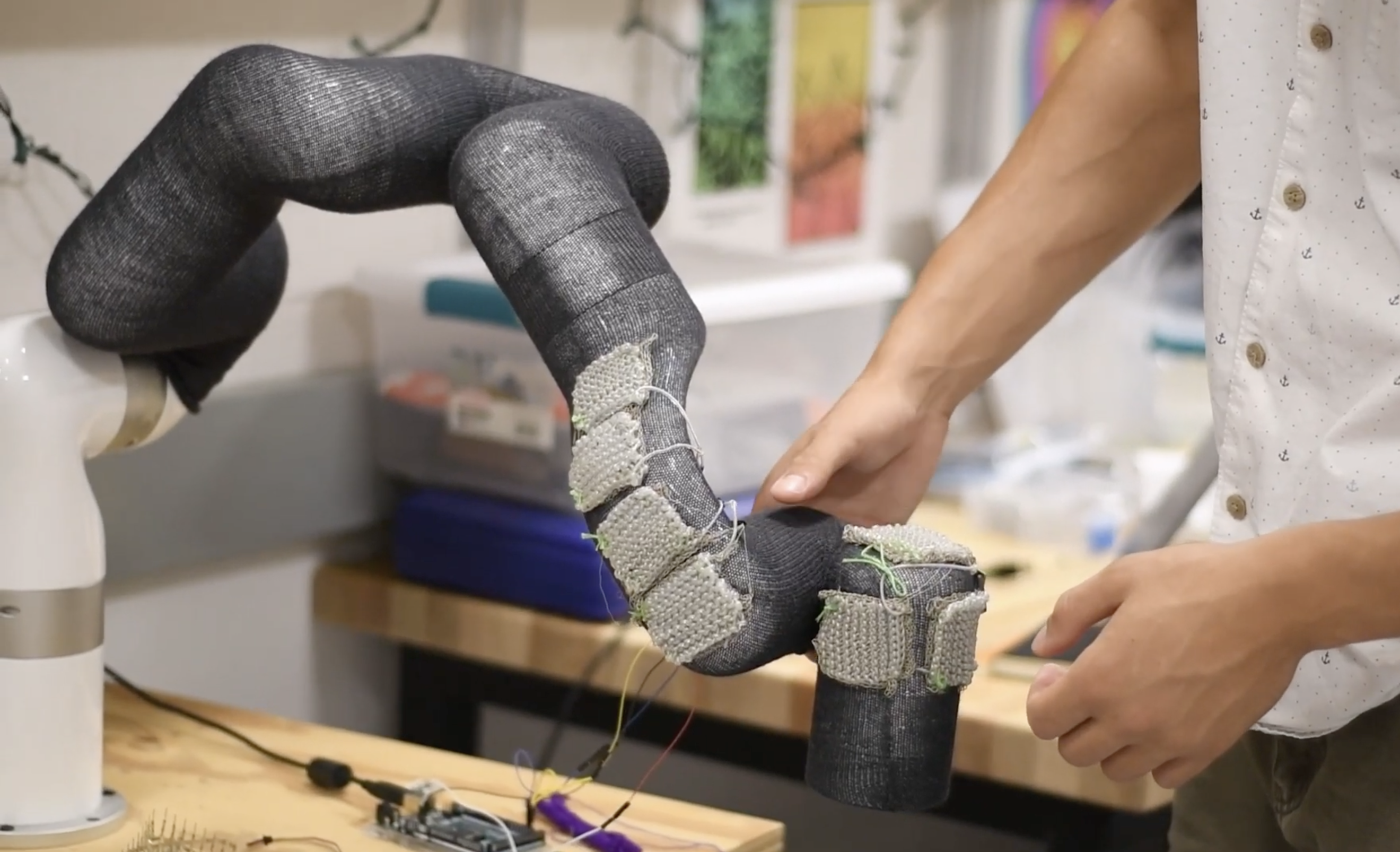

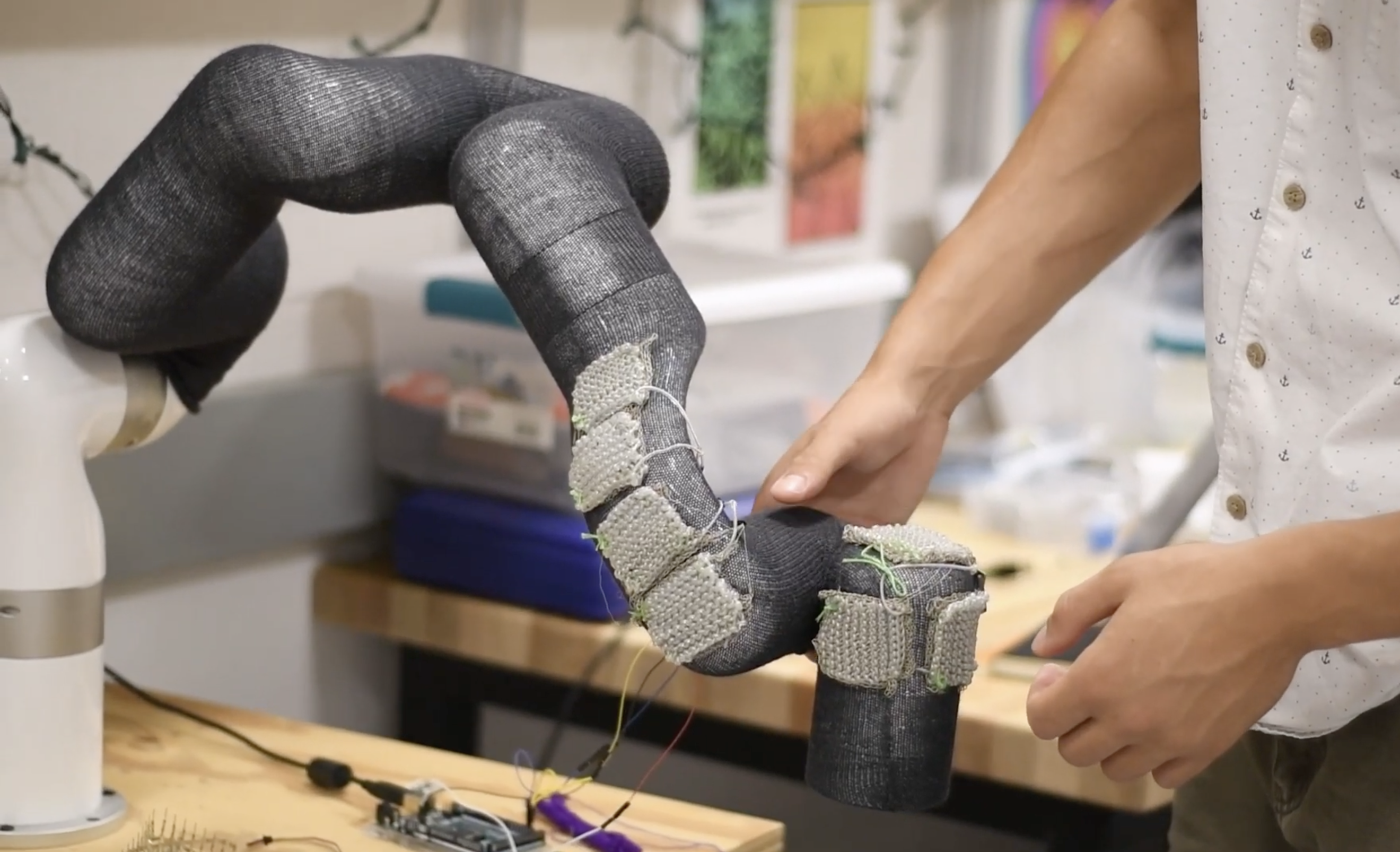

Programmable textile sensing patches for soft robotic systems.

Note (pre-publication): This project is part of ongoing research. To protect unpublished work, I’m not sharing the full knit pattern specification or the complete Knitout/JS codebase publicly. This page focuses on the fabrication workflow, materials stack, and validation methodology. Select details can be shared after publication or in a research interview.

- What I built: A computational pipeline to knit custom resistive pressure sensors.

- Why it matters: Soft robots need sensors that deform with them without breaking contact.

- Proof: Integrated into a multi-zone robotic sleeve interacting with physical objects.

Problem / Goal

Soft robots need sensors that can bend, twist, and compress without breaking contact or adding rigid hardware. Textiles are naturally compliant and body-safe, but making them behave like reliable sensors requires treating knit structure as a structure–property design problem.

My Contribution

I developed the entire fabrication pipeline, moving from manual pattern editing to a script-driven workflow. I designed the knitted structure integrating conductive yarn and silicone tubing for durability. I validated the sensors on benchtop rigs and integrated them into a full robotic sleeve demonstration.

Technical Approach

Fabrication Platform & Materials

I monitored fabrication on a Shima Seiki SWG091N2 WholeGarment machine. The material stack combines conductive yarn for sensing with silicone tubing integrated directly into the knit structure.

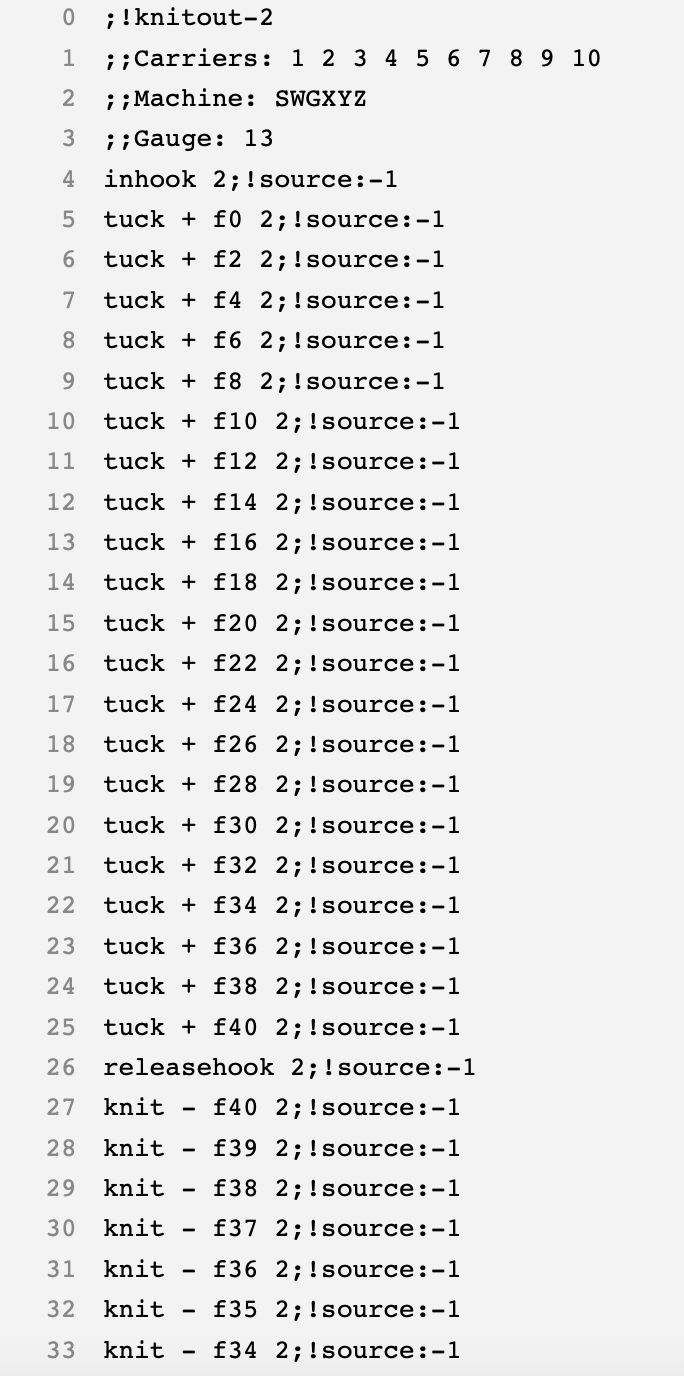

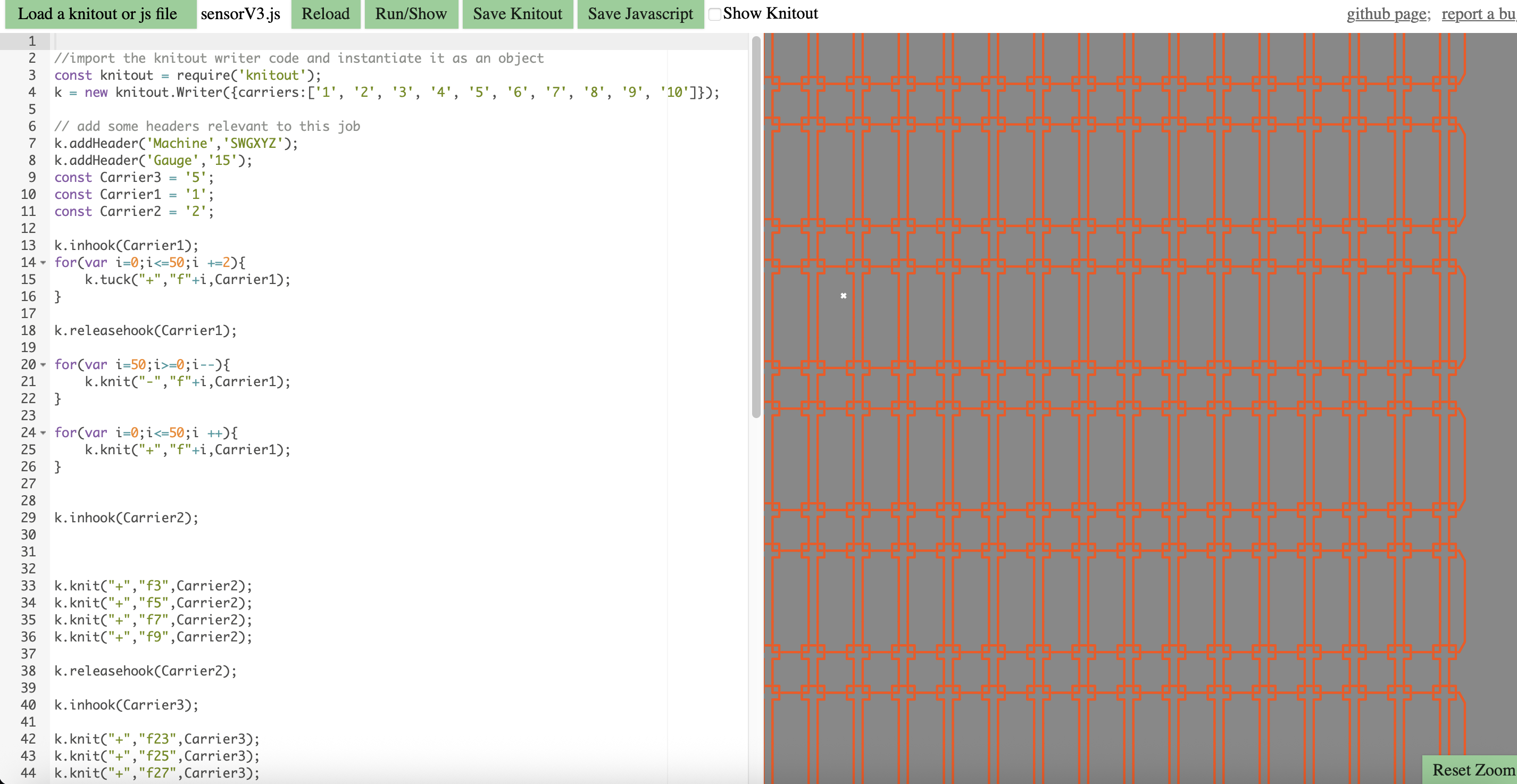

Computational Pipeline (JS → Knitout)

I built a JavaScript-based pipeline to generate Knitout machine instructions. This allows for repeatable pattern generation from high-level parameters.

Validation / Results

Validation is ongoing with cyclic deformation tests (10k cycles) to measure sensitivity, hysteresis, and drift. Early results show reliable signal response.

Lessons + Next Steps

- Scale the sensor array to full‑arm coverage.

- Explore alternative conductive materials (e.g., graphene‑coated yarn).

- Automate calibration using machine‑learning models.

Gallery