Thermal Wearables

Knitted heating interfaces with closed-loop PID control for safe regulation.

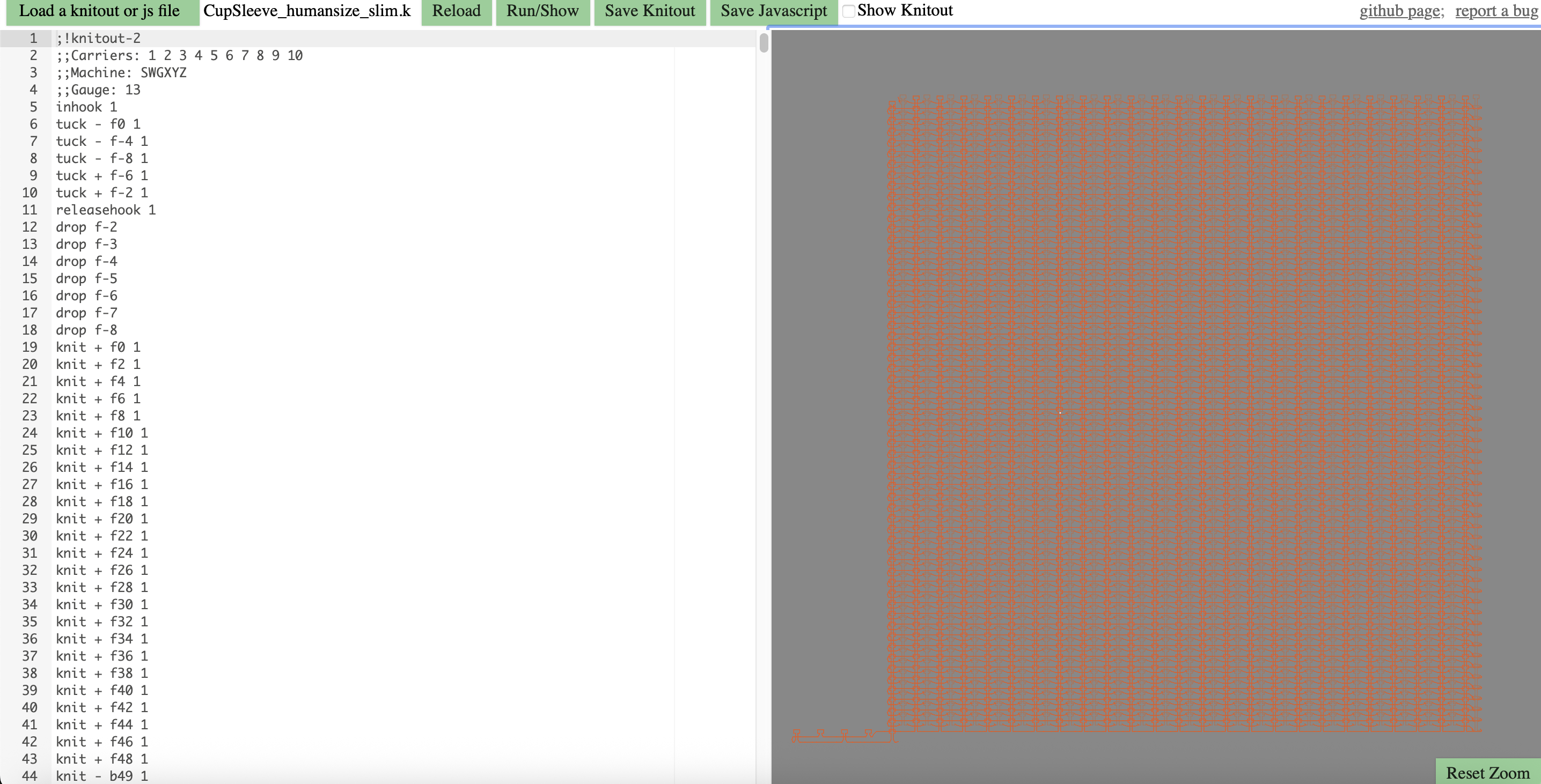

Note (pre-publication): This project is part of ongoing research. To protect unpublished work, I’m not sharing the full knit pattern specification or the complete Knitout/JS codebase publicly. This page focuses on the fabrication workflow, materials stack, and validation methodology. Select details can be shared after publication or in a research interview.

- What I built: Closed-loop thermal regulation system for wearable knit heaters.

- Why it matters: Practical wearables need fast warm-up and stable safety controls despite body movement.

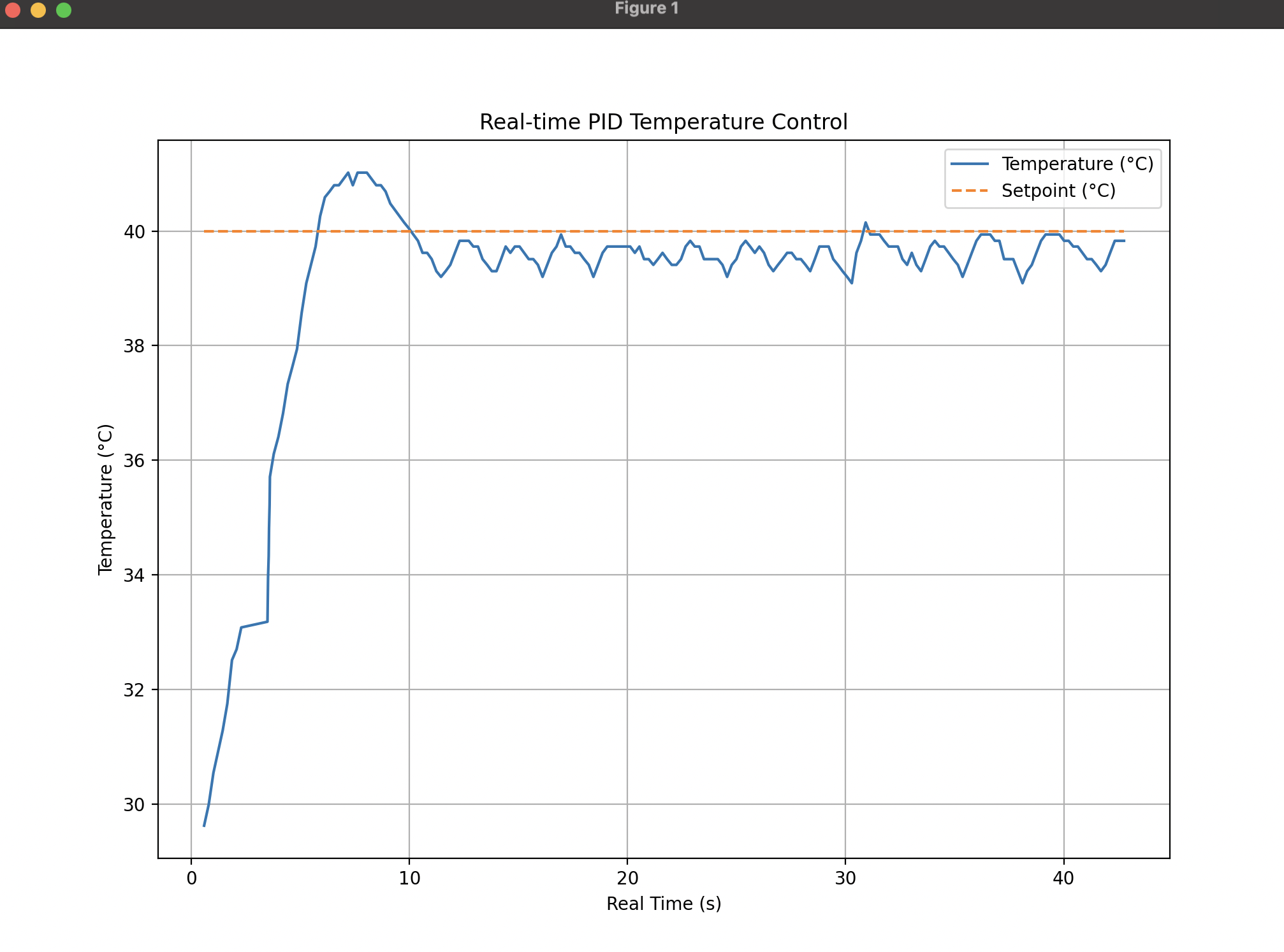

- Proof: Validated PID implementation with real-time temperature tracking plots.

Problem / Goal

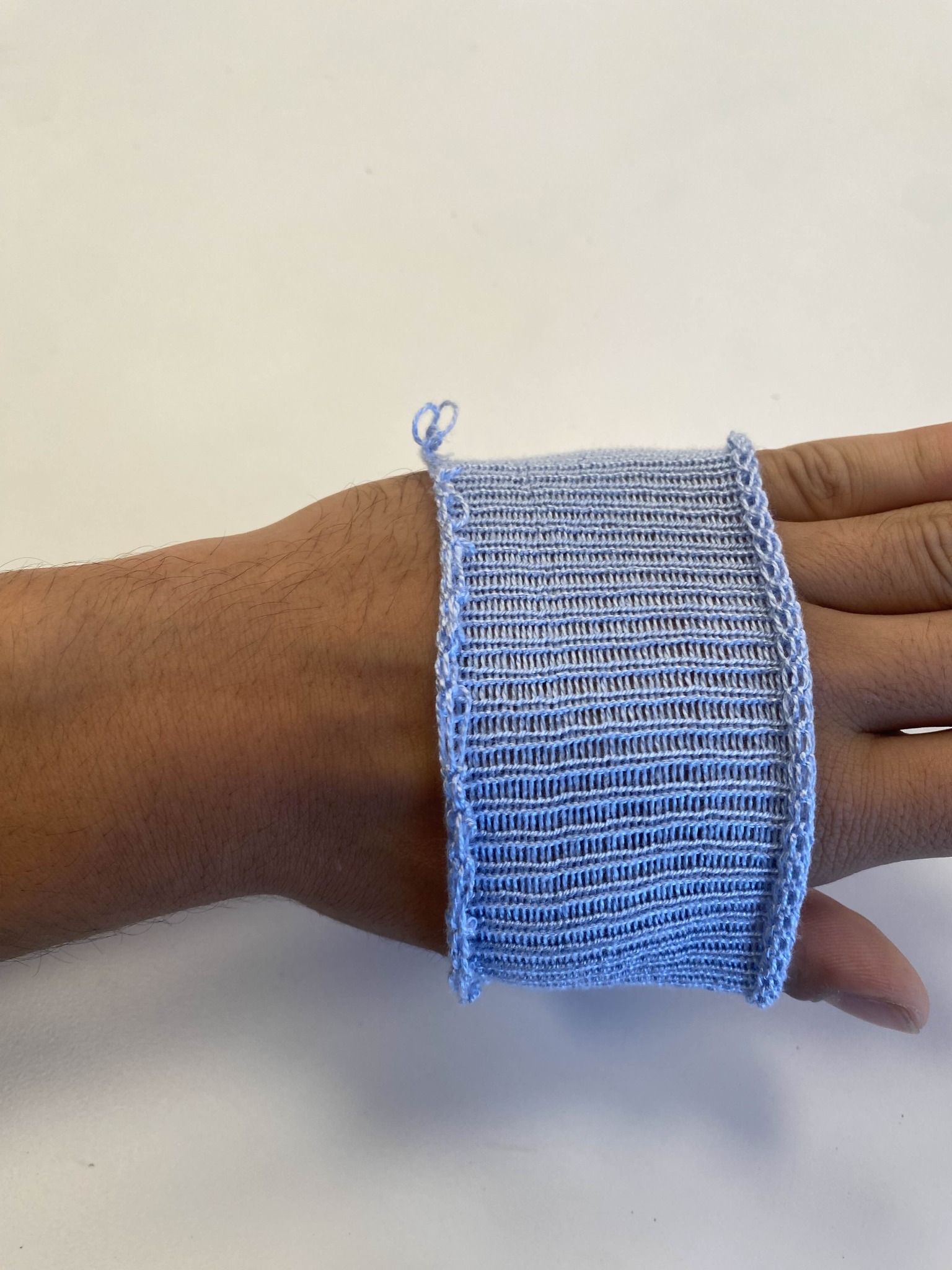

Wearable heating isn’t just about turning power on. Practical systems need fast warm-up without overshoot and stable regulation under changing contact and airflow conditions. This project treats the textile heater + fabrication constraints + control loop as one coupled system.

My Contribution

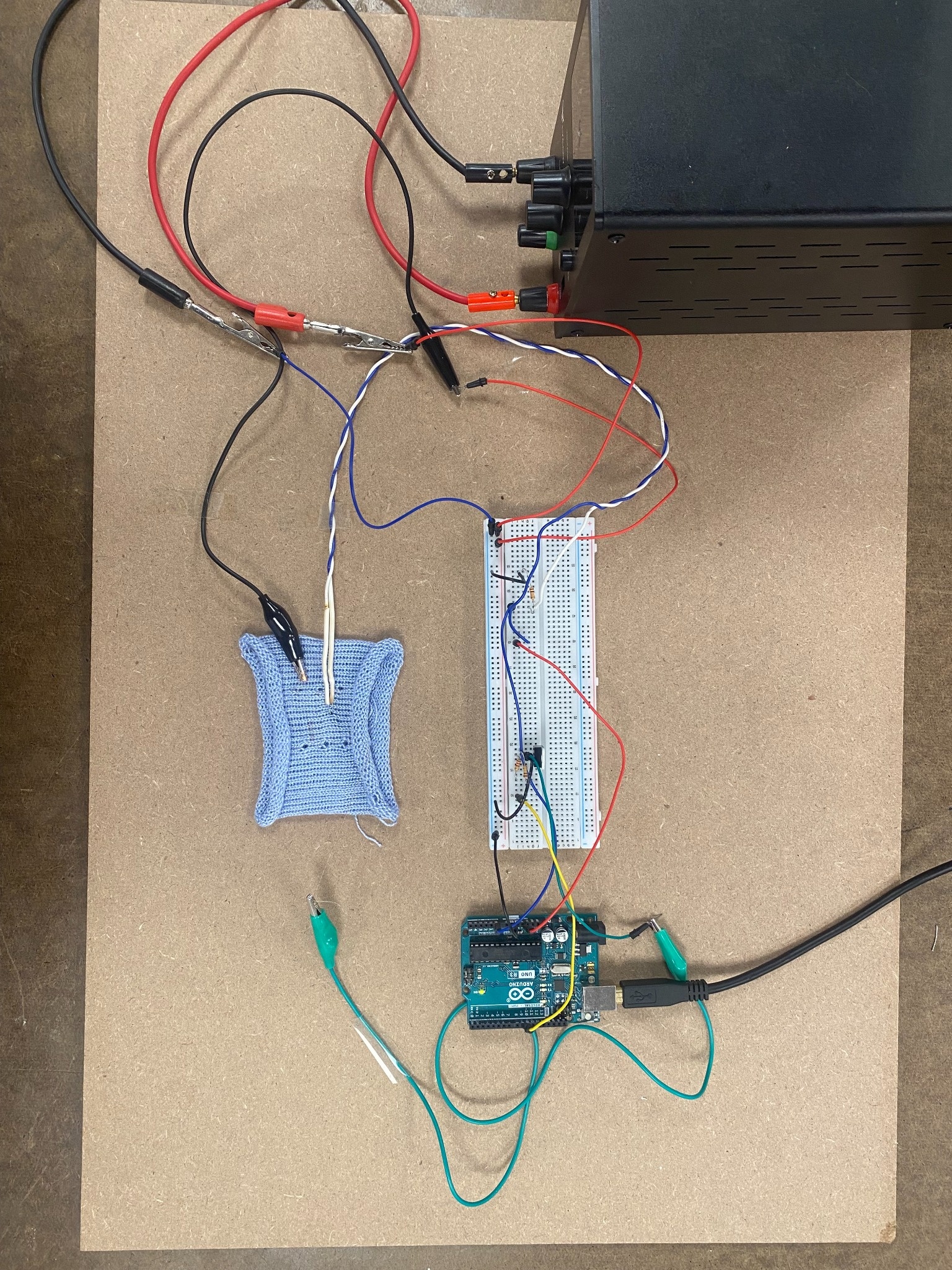

I built the textile heating elements and integrated them into soft substrates. I developed the custom Arduino firmware for closed-loop PID control, ensuring safety and stability. I also built the Python-based testing workflow to log and visualize real-time thermal performance.

Technical Approach

System Design & Fabrication

The heaters are knitted on a Shima Seiki SWG091N2 machine using conductive yarn routing (proprietary) integrated into a woolen substrate. The system includes a microcontroller-based driver and thermistor feedback.

Control & Software

I implemented a real-time PID loop on Arduino to track temperature setpoints. The Python plotting suite reads serial streams to visualize step response and regulation error, enabling rapid tuning of Kp, Ki, and Kd gains.

Validation / Results

The system successfully tracks target temperatures with minimal overshoot after tuning. The plots below show the step response during a warm-up cycle.

Lessons + Next Steps

- improve response under changing contact conditions (airflow, pressure)

- move from breadboard prototype to a more wearable electronics package (robust wiring/strain relief)

- expand evaluation (repeatability across runs, drift, and perception thresholds)

Gallery